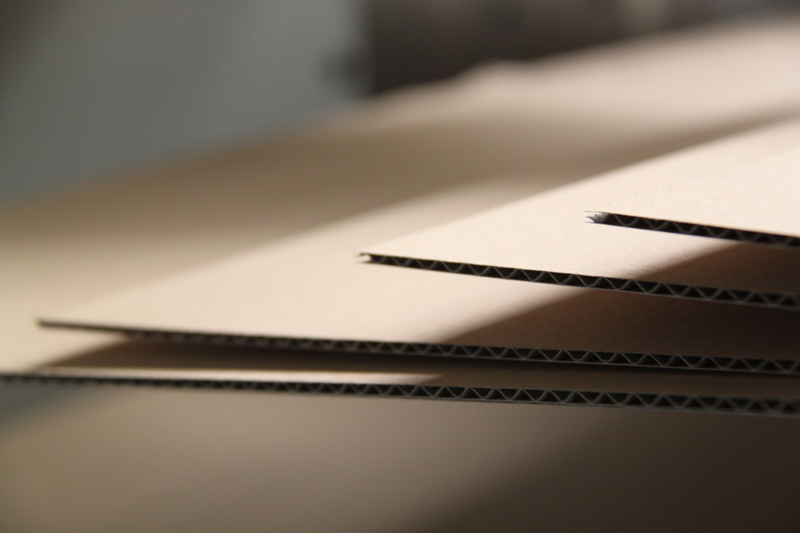

Packaging technologist (m/f/d)

As a packaging technologist, you are choosing a technical profession with a future!

Challenging tasks make this training very attractive.

In our company …

As a packaging technologist, you are choosing a technical profession with a future!

Challenging tasks make this training very attractive.

In our company …

As a machine and plant operator (m/f/d) in our company, you will have a varied and future-proof job in which you can continuously develop your skills. Good manual skills are essential for this role.

“With the largest investment since the company was founded in 1980, we are consolidating our market position, increasing internal added value, creating redundancy for our Göpfert Inliner and improving quality …

As a packaging technologist, you are choosing a technical profession with a future!

Challenging tasks make this training very attractive.

In our company …

As a machine and plant operator (m/f/d) in our company, you will have a varied and future-proof job in which you can continuously develop your skills. Good manual skills are essential for this role.

“With the largest investment since the company was founded in 1980, we are consolidating our market position, increasing internal added value, creating redundancy for our Göpfert Inliner and improving quality …

We invite you to get to know us a little better in this section. What do we stand for? What do we do? What problems do we solve for our customers in the market?

We have identified the following core competencies as part of a customer satisfaction survey. These 5 pillars of success form the foundation of our activities and demonstrably guarantee our customers added value.

When designing our logistics concept, we focused on maximizing customer benefit. With above-average, free storage periods of up to 12 months, we guarantee fixed prices for blanket orders and just-in-time delivery of packaging materials. Our own fleet of trucks gives us the necessary flexibility. We ensure that your packaging is delivered to you on time and in the required quantity – quickly, efficiently and for the sake of the environment!

At WFG Wellpappen Freigericht GmbH you can have a career and at the same time achieve a good balance with your private life. To make this possible, we have actively defined working hours together with our employees.

Our 5 pillars of success guarantee our customers added value – today and in the future!

Technology & Productivity

Thanks to a high degree of automation in our production and the resulting high productivity, we ensure that our customers receive prices in line with the market. Various robots and AI tools, such as our self-programmed production planning, further increase efficiency in our production. Our employees are specifically supported in their activities by smart, automated processes.

Modern IT technology enables high flexibility, precise coordination and sets no limits to creativity in the development of custom-made packaging, outer packaging and corrugated cardboard boxes.

We look forward to receiving your message and will process it as quickly as possible.

WFG Wellpappen Freigericht GmbH

Im See 5

63628 Bad Soden-Salmünster

Phone: +49 6056 9190-0

Fax: +49 6056 9190-99

E-mail: info@wfg-verpackung.de

Career: bewerbungen@wfg-verpackung.de

WFG Wellpappen Freigericht GmbH